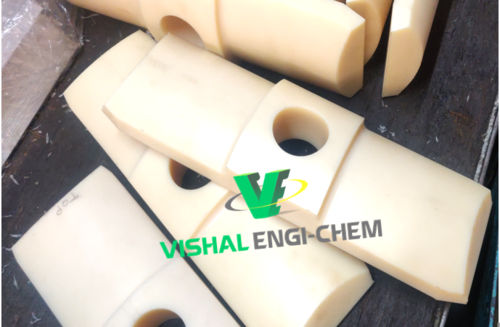

Nylon Rollers

Nylon Rollers Specification

- Product Type

- Industrial

- Color

- Red

Nylon Rollers Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7-10 Days

- Main Domestic Market

- All India

About Nylon Rollers

Nylon Coated Rollers are specialized rollers commonly used in various industrial applications where smooth, low-friction movement is required. The nylon coating provides a smooth and uniform surface finish, reducing friction and allowing for smooth movement of materials or products along the roller. These rollers feature a core material typically made of metal, such as steel or aluminum, which is coated or covered with a layer of nylon or a nylon-based polymer. They can be customized to meet specific application requirements, including variations in size, diameter, length, and load capacity. Nylon Coated Rollers offer a combination of strength, durability, low friction, corrosion resistance, and non-marking properties, making them versatile components for a wide range of industrial conveyor and material handling applications.

FAQs of Nylon Coated Rollers:

Q: What is the material used for Nylon Coated Rollers?

A: The material used for Nylon Coated Rollers is nylon and steel.Q: What are the different types of conveyors available in Nylon Coated Rollers?

A: The different types of conveyors available in Nylon Coated Rollers are Roller Conveyor and Belt Conveyor.Q: What is the color of Nylon Coated Rollers?

A: The color of Nylon Coated Rollers is Red.Q: What is the structure of Nylon Coated Rollers?

A: The structure of Nylon Coated Rollers is Roller.Q: Is there a warranty available for Nylon Coated Rollers?

A: Yes, there is a warranty available for Nylon Coated Rollers.

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7-10 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Mechanical Spare Parts Category

Nylon pad

Minimum Order Quantity : 500 Pieces

Material : Plastic

Type : Electrical

Warranty : Yes

Color : Offwhite

Hardness : Rigid

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free